PERUMIN HUB MINING INNOVATION IN PERU

CHALLENGESMINING 4.0

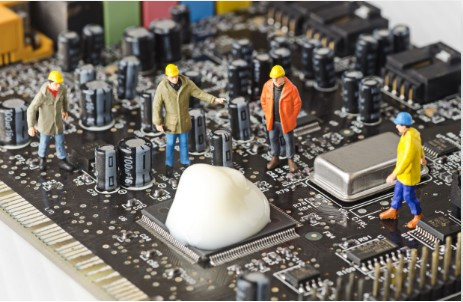

Digital transformation is a global trend that is redefining the mining industry. The introduction of emerging technologies such as artificial intelligence, real-time data analytics, and automation has improved operational efficiency and reduced risks. The use of technology can reduce workers' exposure to operational hazards and minimize environmental impact through better resource management. However, Peruvian mining still faces challenges in effectively adopting and integrating these technologies, due to a lack of digital infrastructure, resistance to change, and the need for more training in advanced tools.

How can we improve operational efficiency and productivity using emerging technologies, while facilitating their adoption by the workforce?

In Peru, the mining sector faces the challenge of improving operational efficiency in a context of rising costs and stricter regulations. The implementation of technologies such as digital twins, automation, and advanced analytics can optimize processes, reduce input consumption, and enhance real-time decision-making. However, adoption remains difficult due to technological fragmentation, a shortage of data-literate talent (such as data scientists), lack of knowledge about mining processes, resistance to change, and conservative attitudes toward the benefits of adopting new technologies.

Elements of value

Solutions that integrate emerging technologies with existing ones to maximize value and reduce infrastructure/hardware needs..

Solutions that consolidate automation processes (Industry 3.0) as a foundation to progress toward Mining 4.0.

Cost-efficient solutions for data capture, transmission, and usage, with a focus on interoperability.

Solutions that prioritize ease of use, adapting to various levels of digital literacy among personnel. Inclusion of digital literacy components related to Industry 4.0 technologies is valued to reduce knowledge gaps.

Solutions that offer long-term support for technology adoption (continuous training, monitoring of tech advances).

Solutions with a change management approach: training, digital mindset, empowerment, and organizational culture.

Solutions that integrate performance indicators and reports to demonstrate benefits..

Solutions with a focus on prevention, prediction, and prescription through data utilization.

Solutions that promote autonomy in plant operations.

Solutions adapted to Peru’s mining conditions (geography, climate, value chain, etc.), connectivity infrastructure limitations, and enabling instrumentation (tools, sensors that withstand corrosive environments, high temperatures, and areas with poor real-time transmission).

Solutions that include virtual instrumentation (no physical equipment).

Solutions that incorporate cybersecurity measures and comply with the user companies’ policies.

Solutions that integrate Industry 4.0 technologies across the entire value chain: mine production, plant, ports, etc., increasing process efficiency. Involvement of suppliers is also valued.

Solutions that promote collaboration with academia and the use of mining royalties for technology development.

Solutions that promote energy efficiency in plants and greater resource recovery.

Solutions for applying AI in metallurgical processes, such as flotation, to improve efficiency.

How can we minimize risks and improve mining safety with new technologies?

Mining activity demands continuous and thorough protection of workers to minimize accident risk and ensure a safe and healthy work environment. Occupational safety and health are fundamental at all operational stages, beginning with shift changes and extending through every process—from task planning and execution to equipment and facilities maintenance and supervision. This requires a comprehensive safety culture that prioritizes risk prevention, continuous training, and the use of technology as a key ally. From smart sensors to AI for risk prediction, technological solutions can help reduce incidents, enhance safety, and move toward zero-accident operations.

Opportunities and/or Value Elements:

Solutions with smart sensors (physical and virtual) for remote monitoring of operating conditions.

Technological solutions for predicting fatigue, sleep, and behavioral patterns to prevent accidents (e.g., biometric monitoring).

Solutions that maximize training impact and reduce digital literacy gaps (tech literacy).

Solutions that ensure cybersecurity and align with company policies.

Solutions adapted to Peruvian operational conditions (altitude, climate, connectivity, corrosion, etc.).

Virtual instrumentation solutions that reduce costs and speed up adoption.

Solutions that integrate technologies for early accident detection and alert.

Solutions that automate, digitalize, or remotely control high-risk procedures.

Solutions for fast alert and reporting of workplace incidents.

Tech solutions that reduce vehicle-to-vehicle contact.

Solutions with advanced analytics models that process large volumes of operational and safety data for decision-making.

Solutions that consider the employment impacts of tech use and propose mitigation actions.

Tech solutions that reduce personnel exposure in hazardous zones (e.g., advanced geophysical methods, drones for inspection).

Solutions that include suppliers in design and implementation.

Solutions to reduce injuries and improve occupational safety (e.g., use of body support devices like exoskeletons).

How can we optimize mineral exploration and extraction using advanced technologies?

In Peru, it can take around four years from identifying an area of interest to deploying drilling equipment, compared to just eight months to a year in other countries (IIMP, 2025). The exploration stage involves significant investment, which is only recovered if a technically and economically viable mineral deposit is discovered.

Exploration and extraction are complex and costly processes that require constant innovation. In the Peruvian context, mining requires technologies that enable the identification of new deposits with greater precision and efficiency, reducing costs and minimizing environmental impact. Solutions such as machine learning, remote sensing, and automated drilling can significantly contribute to making these processes more sustainable and profitable by improving efficiency and reducing risks.

Opportunities and/or Value Elements:

Tech solutions that minimize personnel interaction with drilling equipment to improve safety and costs.

Solutions that reduce risks from handling pipes during drilling.

Real-time geotechnical monitoring solutions to improve safety and efficiency in drilling.

Solutions that reduce exposure in high-altitude tasks.

Innovative solutions that revisit the basic principles of the mining cycle and unit operations, facilitating adoption and optimization.

Tech solutions to improve safety and efficiency in field sampling during prospecting.

Machine learning-based solutions to improve accuracy in deposit identification.

Tech solutions for automated drilling with minimal environmental impact.

Solutions that promote precision mining to optimize resources and minimize impacts.

Technological solutions to optimize real-time geological modeling.

Practical application solutions using remote sensors and advanced geophysics for fast, cost-efficient exploration.

How can we leverage emerging technologies to prevent, detect, and mitigate illegal mining?

Illegal mining is a critical issue in Peru, with severe environmental damage, loss of human lives, and various negative economic, social, and psychosocial impacts across regions. To tackle this challenge comprehensively, regulatory and governance efforts must be complemented by the use of advanced technologies that enable real-time monitoring and control of illicit activities.

Tools such as artificial intelligence, blockchain for traceability, and surveillance drones can play a crucial role in strengthening oversight and governance of the mining sector. The implementation of such technological solutions can significantly contribute to reducing informal and illegal mining.

Opportunities and/or Value Elements:

Tech solutions integrating artificial intelligence for early identification of illegal activities.

Solutions to improve traceability and control of mineral trade, including the supply chain and inputs like explosives, fuel, and chemicals (e.g., blockchain).

Solutions for constant surveillance in critical areas (e.g., satellite and drone monitoring, image and geospatial data analysis).

Solutions that strengthen governance and oversight in vulnerable territories through accessible and scalable technologies.

Multi-stakeholder approach solutions.

Tech solutions from other industries adapted to the mining sector for oversight, monitoring, and control.